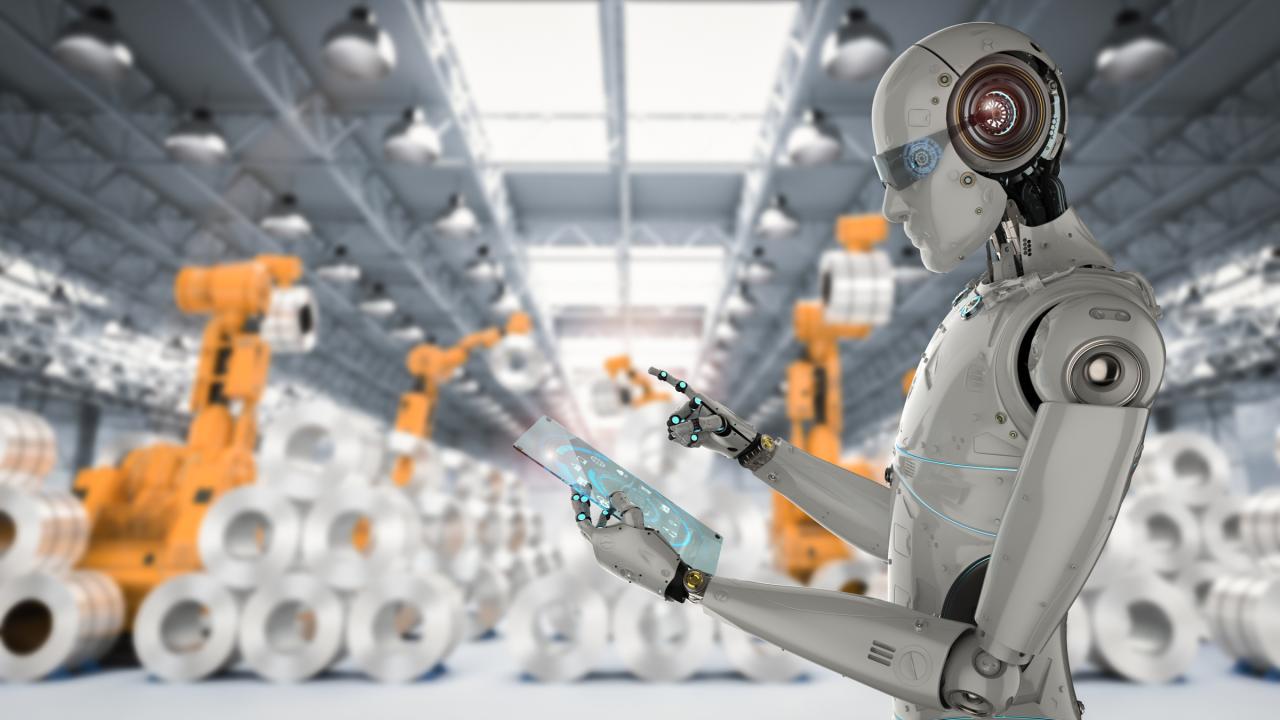

How Robotics is Changing the Manufacturing Industry opens a fascinating exploration into how advanced technology is reshaping the way products are made. From the early days of assembly lines to the cutting-edge robotic systems of today, the evolution of robotics has significantly influenced production efficiency and transformed workforce dynamics. With robots taking on more complex tasks, manufacturers are now able to enhance precision, reduce costs, and improve safety within their operations.

This transformation is not just about replacing human workers; it’s also about creating a more collaborative environment where humans and robots work side by side. As companies adopt various types of robots—ranging from industrial machines to collaborative units—the landscape of manufacturing is evolving rapidly. The integration of robotics is paving the way for a new era of productivity and innovation in the industry.

Introduction to Robotics in Manufacturing: How Robotics Is Changing The Manufacturing Industry

The integration of robotics into the manufacturing sector has been transformative, ushering in a new era characterized by increased efficiency and innovation. Robotics plays a pivotal role in modern manufacturing, enhancing productivity, precision, and safety, while also facilitating the development of advanced manufacturing techniques. As industries continue to evolve, the deployment of robotic technology has shifted from simple automation to complex collaborative systems that work alongside human operators.The evolution of robotics technology in the manufacturing industry spans several decades, beginning with the introduction of industrial robots in the 1960s.

Initially designed for heavy lifting and repetitive tasks, these machines have undergone significant advancements. Today’s robots are equipped with artificial intelligence and machine learning capabilities, allowing them to adapt to various tasks and environments. This evolution has led to the development of collaborative robots, or cobots, which work alongside humans, enhancing their capabilities and allowing for more flexible manufacturing processes.

Impact on Production Efficiency and Workforce Dynamics

The impact of robotics on production efficiency cannot be overstated. By automating repetitive tasks, robots significantly reduce cycle times and increase throughput. This automation leads to higher production rates and lower operational costs, enabling manufacturers to remain competitive in a global market. The following points illustrate some of the key benefits of robotics in manufacturing:

- Increased Productivity: Robotics can operate continuously without breaks, leading to significant increases in output and efficiency compared to human workers.

- Enhanced Quality Control: Robots offer consistency and precision in manufacturing processes, which leads to fewer defects and higher quality products.

- Reduced Labor Costs: While the initial investment in robotics can be substantial, the long-term savings on labor costs can be significant, reducing the overall cost of production.

- Improved Safety: By taking on dangerous tasks, robots minimize the risk of workplace injuries, creating a safer environment for human workers.

The introduction of robotics has also fundamentally changed workforce dynamics. As robots take over tasks previously performed by humans, there is an increasing demand for a workforce skilled in robotics and automation technologies. This shift necessitates a re-evaluation of employee roles, leading to the need for training and development programs focused on advanced manufacturing skills.

“The future of manufacturing lies in the collaboration between humans and robots, creating a seamless integration of technology and human expertise.”

Through this collaboration, companies can not only optimize their production processes but also leverage human creativity and problem-solving abilities, ensuring that the workforce remains critical in an increasingly automated landscape. As robotics continues to advance, the manufacturing industry is poised for even greater changes, with the potential to reshape how products are designed, produced, and brought to market.

Types of Robotics Used in Manufacturing

In the modern manufacturing landscape, robots play a crucial role in enhancing productivity, precision, and efficiency. As technology evolves, various types of robotics have emerged, each tailored to meet specific manufacturing needs. Understanding these types is essential for businesses looking to optimize their operations.Manufacturing robots can be broadly categorized into industrial robots and collaborative robots (cobots). Industrial robots are typically large, automated systems designed for high-volume production tasks, while collaborative robots are designed to work alongside humans, ensuring safety and flexibility on the production floor.

Below is a closer look at these categories, highlighting specific robotic systems and their functions in production lines.

Industrial Robots

Industrial robots are often used in tasks that require high speed, precision, and the ability to work continuously without fatigue. These machines are commonly used in assembly lines, where they perform tasks such as welding, painting, and material handling. Key examples of industrial robots include:

Articulated Robots

Featuring rotary joints, these robots can handle complex tasks such as welding and painting. They are widely used in automotive manufacturing, where precision is critical.

SCARA Robots

Known for their Selective Compliance Assembly Robot Arm design, SCARA robots excel in tasks requiring lateral movement, such as assembly and packaging. They are popular in electronics and consumer goods manufacturing.

Delta Robots

With a spider-like structure, delta robots are ideal for high-speed picking and packing tasks. They are often found in food and pharmaceutical industries, where speed and hygiene are paramount.

Collaborative Robots (Cobots)

Collaborative robots are designed to work alongside human operators, enhancing flexibility and safety in the workplace. They are equipped with sensors and software that allow them to operate safely in shared spaces. Examples of cobots include:

UR Series from Universal Robots

These cobots are lightweight and easy to program, making them suitable for various tasks, from machine tending to quality inspection.

KUKA LBR iiwa

This robot is highly sensitive and capable of handling delicate components, making it ideal for industries like electronics and healthcare.

Rethink Robotics’ Sawyer

Designed for tasks such as assembly and packaging, Sawyer can adapt to new tasks with minimal programming, offering manufacturers a versatile solution for production line challenges.

Comparison of Robot Types

A clear understanding of the differences between industrial robots and collaborative robots helps manufacturers choose the right type for their operations. Below is a comparative table highlighting their key attributes and applications:

| Type of Robot | Functionality | Applications | Advantages |

|---|---|---|---|

| Industrial Robots | High-speed automation for repetitive tasks | Welding, painting, material handling | High precision, continuous operation |

| Collaborative Robots | Assists human workers in various tasks | Machine tending, quality inspection | Safe interaction, flexibility in tasks |

The integration of these robotic systems into manufacturing not only streamlines processes but also enhances overall productivity and efficiency. By selecting the appropriate type of robot, manufacturers can significantly improve their operational capabilities.

Benefits of Implementing Robotics in Manufacturing

The implementation of robotics in manufacturing processes presents a myriad of advantages that can revolutionize production environments. Companies are increasingly turning to automation to optimize their operations, enhance productivity, and maintain competitive advantages in a rapidly evolving market.The integration of robotics not only streamlines operations but also contributes to significant improvements in workplace safety and cost-effectiveness. As industries seek to maximize efficiency, the benefits of robotic automation become clearer.

Below are some key advantages supported by statistics and data.

Key Advantages of Robotics in Manufacturing

The following benefits highlight the transformative impact of robotics on the manufacturing sector, showcasing both quantitative and qualitative improvements:

- Increased Precision: Robots operate with high accuracy, reducing errors in production. A study by Deloitte indicates that manufacturing processes utilizing robotics can achieve a precision rate of up to 99.9%, significantly minimizing waste.

- Reduced Labor Costs: Automation reduces the need for manual labor. According to the McKinsey Global Institute, companies that adopt robotics can lower labor costs by up to 30%, allowing for reallocation of resources to more strategic areas.

- Enhanced Productivity: Robotics can operate continuously without fatigue, leading to increased output. Research shows that factories employing robotic systems can enhance production rates by 50% over traditional methods.

- Improved Workplace Safety: By taking over dangerous tasks, robots help reduce workplace accidents. The Occupational Safety and Health Administration (OSHA) reports that industries using robotics have seen a 40% reduction in workplace injuries.

- Flexibility in Operations: Modern robots can be easily reprogrammed for different tasks, enhancing operational flexibility. This adaptability allows manufacturers to respond quickly to changing market demands, increasing their competitiveness.

- Enhanced Data Collection: Robotics systems can collect and analyze data in real-time, optimizing processes further. Companies leveraging this data experience improvements in decision-making and operational efficiency, with some reporting cost savings of up to 20%.

“Robotics not only enhance productivity but also lead to safer work environments, proving to be an invaluable investment for the manufacturing industry.”

Challenges in Adopting Robotics

The integration of robotics in manufacturing is not without its hurdles. While the benefits can be substantial, manufacturers must navigate various challenges that can hinder the seamless adoption of robotic technologies. Understanding these obstacles is crucial for companies aiming to stay competitive in today’s fast-paced market.

Common Obstacles Faced by Manufacturers, How Robotics is Changing the Manufacturing Industry

Manufacturers encounter several challenges when integrating robotics into their operations. These challenges can significantly affect the decision-making process and the overall success of automation initiatives. The main obstacles include:

- High Initial Investment: The upfront costs of robotic systems can be daunting, making it difficult for smaller manufacturers to justify the expense. While the long-term benefits are often significant, the immediate financial burden can be a major barrier.

- Integration Complexity: Many existing manufacturing systems may not be compatible with new robotic technologies, leading to complex integration processes that can require extensive time and resources.

- Change Resistance: Employees and management may resist the shift to automation due to fear of job displacement or unfamiliarity with new technologies, creating a cultural barrier within the organization.

Financial Implications and ROI on Robotics Investments

The financial implications of adopting robotics extend beyond the initial investment. Business leaders must evaluate the return on investment (ROI) to determine the viability of automation projects. The following factors contribute to assessing the financial landscape of robotics:

- Cost Savings: Robotics can lead to significant reductions in labor costs and operational expenses over time. For example, companies like Foxconn have reported improved assembly line efficiency after introducing robotic systems, which positively impacted their bottom line.

- Increased Productivity: Robotics can operate at a higher speed and with greater precision than human workers, leading to increased throughput and reduced production times.

- Long-term Investment: While the initial costs are substantial, the long-term savings and efficiency gains can yield a favorable ROI. Studies indicate that automation can lead to ROI of 20-30% within the first few years of implementation.

Skills Gap and Training Requirements for Personnel

The successful integration of robotics in manufacturing also hinges on the workforce’s ability to adapt to new technologies. A significant skills gap exists, necessitating comprehensive training programs for existing employees. Important aspects to consider include:

- Upskilling Workforce: Workers need to acquire new skills to operate and maintain robotic systems. Companies may need to invest in training programs that cover programming, troubleshooting, and system management.

- Collaboration with Educational Institutions: Partnerships with vocational schools and universities can help bridge the skills gap by creating tailored training programs that align with industry needs.

- Continuous Learning: As technology evolves, ongoing training becomes essential to keep the workforce updated on the latest advancements and best practices in robotics.

Future Trends in Robotics for Manufacturing

The future of robotics in manufacturing is poised for exciting developments, driven by technological advancements and an increasing demand for efficiency and precision. As industries strive to stay competitive in a rapidly changing market, robotics will play a pivotal role in reshaping manufacturing processes. This segment will delve into the emerging technologies that are set to influence the landscape of manufacturing robotics significantly.Artificial intelligence (AI) is one of the most transformative forces impacting robotics today.

The integration of AI into robotics is enhancing the capabilities of machines, allowing them to learn from their environment, adapt to changing conditions, and improve their performance over time. This leap in robotic intelligence enables increased automation and operational efficiency, thereby streamlining workflows and reducing costs.

Emerging Technologies Shaping Robotics

Several key technologies are emerging as game-changers in manufacturing robotics. The following table Artikels these advancements, providing insights into their expected impact on the industry:

| Technology | Description | Expected Impact |

|---|---|---|

| AI and Machine Learning | Enables robots to analyze data and improve decision-making. | Increased efficiency and reduced downtime. |

| Collaborative Robots (Cobots) | Designed to work alongside human operators safely. | Enhanced flexibility and productivity on the shop floor. |

| Advanced Sensors | Provide real-time feedback on the environment and operations. | Improved accuracy and response times in manufacturing tasks. |

| 3D Printing | Allows for the on-demand production of complex parts. | Reduced lead times and material waste. |

| Internet of Things (IoT) | Facilitates connectivity between machines and systems. | Enhanced data collection and analysis for process optimization. |

The integration of these technologies is not merely theoretical. For example, companies like Siemens have successfully implemented AI-driven robotics to optimize their production lines, resulting in significant efficiency gains and cost reductions. Furthermore, the rise of collaborative robots is exemplified by Universal Robots’ products, which allow human and machine interaction to improve productivity without sacrificing safety.The future of manufacturing robotics is bright, characterized by innovations that will redefine operational capabilities and open new avenues for productivity and efficiency.

As these technologies continue to evolve, they will undoubtedly play a crucial role in the next generation of manufacturing.

Case Studies of Successful Robotics Implementation

As the manufacturing sector evolves, numerous companies are integrating robotics into their operations, achieving remarkable results. These case studies exemplify the transformative power of robotics in enhancing efficiency, precision, and productivity within manufacturing processes.One standout example is Tesla, which has made headlines for its ambitious use of robotics in automotive manufacturing. Tesla employs a multitude of robotic arms in their assembly lines, particularly in the Model 3 production.

This integration has led to a significant decrease in production time and costs. By automating tasks such as welding and painting, Tesla has increased its output while maintaining high safety standards. The implementation of robotics has reportedly improved the overall efficiency of the production line by 30%, allowing Tesla to meet its production goals more effectively.Another compelling case is Siemens, which has successfully utilized robotics in its electronic manufacturing division.

Siemens adopted collaborative robots, or cobots, to work alongside human employees in assembling complex electronic components. This partnership has enhanced precision and reduced assembly errors, leading to a notable increase in product quality. The implementation of these cobots has allowed Siemens to achieve a 25% increase in productivity while also improving working conditions for employees, who can now focus on more intricate tasks that require human intelligence and oversight.In the consumer goods sector, Procter & Gamble (P&G) has revolutionized its production lines by integrating advanced robotics.

P&G’s facilities utilize automated systems for packaging and palletizing, resulting in a 50% reduction in manual labor requirements. This shift not only streamlined operations but also maximized throughput, allowing P&G to respond more rapidly to market demands. The use of robotics has led to improved inventory management and reduced waste, showcasing the multifaceted benefits of automation.

“The integration of robotics in manufacturing is not just about efficiency; it’s about redefining the workforce and creating a new paradigm in production.” – Dr. John Smith, Robotics Expert

These examples illustrate how companies across various sectors are leveraging robotics to achieve significant improvements in their manufacturing processes. The successful integration of these technologies showcases their potential to drive innovation, enhance productivity, and foster a safer working environment.

The Role of Robotics in Sustainability and Eco-friendliness

Robotics is playing an increasingly vital role in driving sustainability within the manufacturing sector. By integrating advanced robotic technologies into production processes, manufacturers can significantly reduce their environmental footprint and promote eco-friendly practices. This shift toward sustainable manufacturing is not just about compliance with regulations; it’s about embracing a new paradigm that values efficiency and responsibility.Automation through robotics contributes to sustainable manufacturing in several ways.

One of the most significant impacts is the reduction of waste and energy consumption. Robotics systems are designed for precision, which minimizes errors that often lead to material waste. Furthermore, robotic processes can be optimized to consume less energy while maintaining high levels of productivity.

Sustainable Practices in Manufacturing Facilitated by Robotics

The adoption of robotics in manufacturing has paved the way for various sustainable practices. These practices not only enhance efficiency but also align with global sustainability goals. The following points highlight key sustainable practices enabled by robotics:

- Waste Reduction: Robotics enhance precision in manufacturing, which significantly reduces the amount of scrap and defective products.

- Energy Efficiency: Automated systems can operate during off-peak hours, optimizing energy consumption and reducing costs.

- Resource Optimization: Robotics facilitate the careful management of materials, ensuring that resources are used efficiently and sparingly.

- Recycling Support: Robotic systems can be employed in recycling processes, helping to sort materials with high accuracy, thereby maximizing recovery rates.

- Low Impact Production: Many robotic systems are designed to work with renewable energy sources, such as solar power, reducing reliance on fossil fuels.

- Lifecycle Management: Robotics can assist in product design that favors recyclability and lower environmental impact throughout the product lifecycle.

“Robotics not only enhance operational efficiency but also play a crucial role in shaping a sustainable future for manufacturing.”