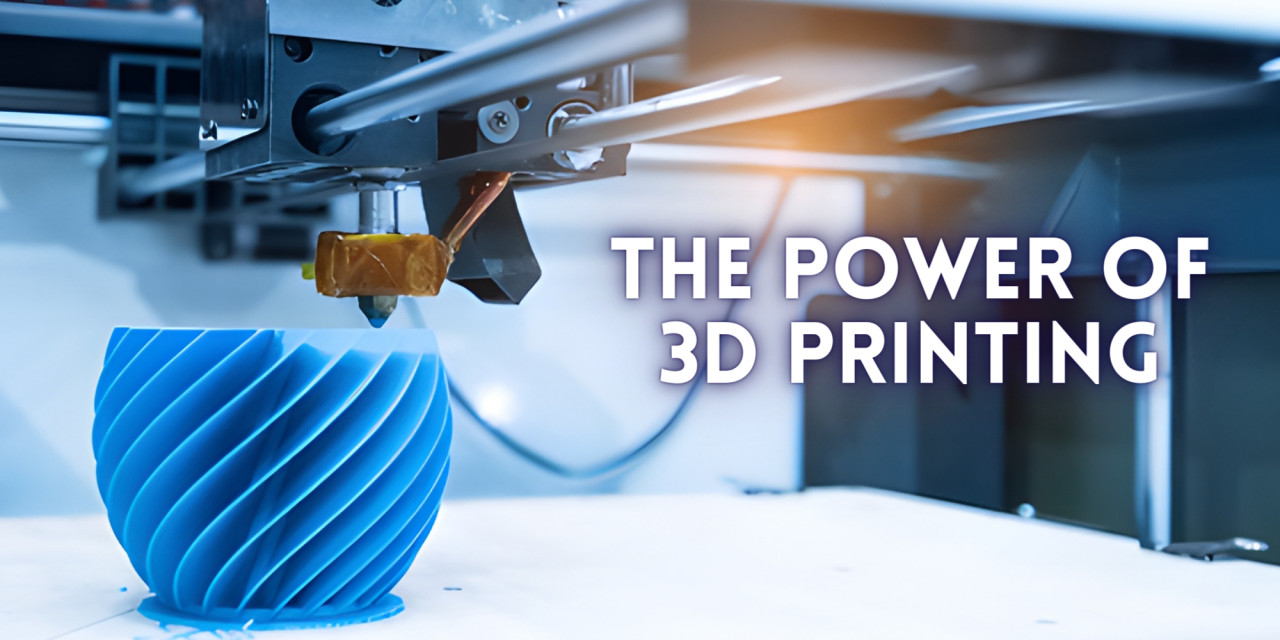

How 3D Printing is Revolutionizing Manufacturing has become a hot topic in today’s industrial landscape. This innovative technology has swiftly emerged as a disruptive force, transforming traditional manufacturing methods and introducing new possibilities for design and production. Unlike conventional techniques, 3D printing allows for unprecedented flexibility and efficiency, enabling manufacturers to create complex structures with remarkable speed and precision.

As industries embrace this cutting-edge approach, the significance of 3D printing is evident. From reducing material waste to cutting costs, the benefits are numerous, leading to a fundamental shift in how products are conceived and produced across various sectors.

Introduction to 3D Printing in Manufacturing: How 3D Printing Is Revolutionizing Manufacturing

The emergence of 3D printing technology has marked a significant shift in the manufacturing sector, revolutionizing how products are designed, produced, and distributed. Originating in the 1980s, this innovative method has evolved from simple prototyping tools to complex production systems that allow for the creation of intricate designs and components across various industries. Today, 3D printing continues to gain traction due to advancements in materials and processes, making it an indispensable part of the modern manufacturing landscape.D printing, or additive manufacturing, differs fundamentally from traditional manufacturing methods such as subtractive machining, which involves cutting away material from a solid block.

In contrast, 3D printing builds objects layer by layer, allowing for more complex geometries and reduced material waste. This process not only streamlines production but also reduces lead times, enabling manufacturers to respond rapidly to market demands. Furthermore, the significance of 3D printing in modern manufacturing lies in its ability to facilitate customization and innovation, transforming ideas into tangible products with unprecedented speed and precision.

Benefits of 3D Printing in Manufacturing

The advantages of 3D printing in manufacturing extend beyond mere efficiency; they encompass a range of benefits that can dramatically impact production capabilities. Here are key benefits to consider:

- Cost Reduction: 3D printing minimizes material waste and reduces labor costs, leading to significant savings in production expenses. For instance, companies like General Electric have adopted 3D printing for jet engine components, resulting in a 90% reduction in material waste.

- Enhanced Design Flexibility: Designers can create complex structures that are often impossible to achieve with traditional methods. An example is the lattice structures used in aerospace components that reduce weight while maintaining strength.

- Rapid Prototyping: Manufacturers can quickly produce prototypes to test designs and functionality, significantly shortening development cycles. Companies such as Nike use 3D printing to create prototypes for footwear, allowing for faster iterations based on consumer feedback.

- On-Demand Production: 3D printing facilitates just-in-time manufacturing, reducing the need for large inventories. This is particularly beneficial in industries like healthcare, where custom implants can be produced as needed.

“3D printing not only reshapes how we manufacture but also how we envision products.”

By harnessing these advantages, businesses can improve their competitiveness and foster innovation, paving the way for a new era of manufacturing that prioritizes efficiency, customization, and sustainability.

Benefits of 3D Printing in Manufacturing

The integration of 3D printing in manufacturing processes brings forth a myriad of advantages that make it a game-changer in various industries. As businesses strive for efficiency and innovation, 3D printing stands out by delivering significant cost benefits, enhanced design capabilities, and reduced material waste. These factors collectively revolutionize how products are conceived, developed, and brought to market.

Cost-Saving Advantages of 3D Printing

One of the most compelling benefits of 3D printing is its potential for cost savings. Traditional manufacturing often involves high costs associated with tooling, material procurement, and labor. In contrast, 3D printing allows for significant reductions in these areas. For instance, companies can produce complex parts without the need for expensive molds and tools, which can cost thousands or even millions of dollars.

This leads to lower upfront investment and quicker turnaround times for product development. A notable example is the aerospace industry, where Boeing has reported a 90% reduction in production costs for certain components by utilizing 3D printing technologies.

Design Flexibility in 3D Printing

D printing introduces unparalleled design flexibility that traditional manufacturing methods cannot achieve. Designers can create intricate geometries and custom features that were previously impossible or prohibitively expensive to produce. The additive nature of 3D printing allows for the production of lightweight structures that maintain strength, catering to industries that prioritize performance, such as automotive and aerospace. For example, General Electric has leveraged 3D printing to create fuel nozzles for jet engines that are not only lighter but also more efficient, enhancing overall aircraft performance.

Reduction of Material Waste through Additive Manufacturing

Additive manufacturing, the core principle of 3D printing, inherently minimizes material waste compared to subtractive manufacturing processes. Traditional methods often involve cutting away excess material from a larger block, leading to significant waste. In contrast, 3D printing builds objects layer by layer, using only the material necessary for the final product. This efficiency not only conserves resources but also lowers costs associated with material disposal.

A case in point is the furniture industry, where companies like IKEA are adopting 3D printing to create customized pieces with minimal waste, aligning with sustainable practices and reducing their environmental footprint.

Applications of 3D Printing in Various Industries

D printing technology has made significant inroads into a multitude of industries, transforming traditional manufacturing methods and enhancing product development processes. By enabling rapid prototyping, customization, and cost-effective production, 3D printing is paving the way for innovation across sectors such as aerospace, automotive, healthcare, and more.The versatility of 3D printing is evident in its diverse applications. Below is a table that highlights various industries leveraging this technology, along with examples of how 3D printing is being effectively utilized in each sector.

| Industry | Application | Example |

|---|---|---|

| Aerospace | Production of lightweight components | NASA’s 3D-printed rocket engine parts |

| Automotive | Rapid prototyping of parts | Ford’s 3D printing for production tooling |

| Healthcare | Custom prosthetics and implants | 3D-printed dental implants by Materialise |

| Consumer Goods | Personalized products | Adidas’s 3D-printed sneakers |

| Construction | Building structures | ICON’s 3D-printed homes |

Case Studies of Successful Implementations

Several organizations have successfully integrated 3D printing into their manufacturing workflows, leading to notable advancements. In the aerospace sector, General Electric has utilized 3D printing for the production of fuel nozzles for their LEAP jet engines, reducing the component count from 18 parts to just one, effectively lowering manufacturing costs and improving performance. In the automotive industry, BMW has embraced 3D printing for both prototyping and series production.

By producing lightweight parts for their vehicles, the company has improved fuel efficiency and overall vehicle performance, showcasing a successful blend of innovation and sustainability.Healthcare has seen transformative impacts, particularly with the case of 3D-printed personalized implants. For instance, a patient requiring a complex jaw reconstruction benefited from a custom 3D-printed titanium implant, resulting in a successful surgery and improved recovery time.

This case exemplifies how tailored solutions can enhance patient outcomes while reducing surgical risks.

Innovative Products Developed Through 3D Printing

Beyond traditional applications, 3D printing has given rise to inventive products that push the boundaries of design and functionality. Noteworthy examples include:

*Bioprinted Organs*

Research institutions are making strides towards printing functional organs using bio-ink, aiming to address the organ transplant shortage.

*Fashion and Accessories*

Designers are exploring 3D printing to create intricate jewelry and fashion pieces, allowing for unique and customizable designs with minimal waste.

*Space Exploration Tools*

The European Space Agency has begun 3D printing tools and spare parts aboard the International Space Station, reducing the need for resupply missions from Earth.These innovative applications highlight the transformative potential of 3D printing, showcasing its ability to revolutionize product development and manufacturing across diverse industries.

Comparison of 3D Printing Techniques

D printing has evolved into a remarkable technological advancement that relies on various techniques, each with its unique set of features, materials, and applications. Understanding the differences among these techniques is crucial for manufacturers looking to leverage the benefits of 3D printing optimally.

FDM, SLA, and SLS Techniques

Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS) are three of the most prominent 3D printing techniques used in manufacturing today. Each technique offers distinct advantages and uses different materials, catering to various needs in the industry.FDM is one of the most popular and accessible techniques, primarily due to its cost-effectiveness and ease of use. SLA, on the other hand, provides high precision and a smooth finish, making it ideal for intricate designs.

SLS excels at creating durable parts from a variety of materials, with applications ranging from prototypes to end-use products. Below is a comparison of these techniques, including their strengths and weaknesses.

Materials and Applications

Understanding the materials associated with each 3D printing technique helps clarify their applications. Here’s a breakdown of the materials commonly used:

- FDM: Utilizes thermoplastics such as PLA, ABS, and PETG. Common applications include prototypes, hobbyist projects, and simple end-use products.

- SLA: Uses photopolymer resins that cure under UV light. Applications range from highly detailed prototypes in jewelry to dental and medical models.

- SLS: Works with powdered materials such as nylon and metal. It’s ideally suited for functional prototypes, complex geometries, and low-volume production runs.

Strengths and Weaknesses

Each technique has its own set of strengths and weaknesses, which are important to consider when selecting the appropriate method for a specific application. Below are key points summarizing these aspects:

- FDM:

- Strengths:

Cost-effective, easy to use, and suitable for a wide range of materials.

- Weaknesses:

Lower resolution and surface finish quality compared to SLA and SLS.

- Strengths:

- SLA:

- Strengths:

High detail and superior surface finish, ideal for intricate designs.

- Weaknesses:

Resins can be expensive and may require post-processing to achieve desired results.

- Strengths:

- SLS:

- Strengths:

Ability to create complex geometries with strong, durable parts.

- Weaknesses:

Higher equipment and material costs, along with longer processing times.

- Strengths:

By understanding these differences in 3D printing techniques, manufacturers can make informed decisions that best suit their production needs and product specifications.

The Future of 3D Printing in Manufacturing

As 3D printing technology continues to evolve, its future in manufacturing shows immense potential for innovation and transformation. Emerging trends promise to reshape various aspects of production, from design to material usage, making processes more efficient and tailored to consumer needs. The advancements in this field indicate a shift towards more sustainable, customizable, and intricate manufacturing capabilities that could redefine industry standards.

Emerging Trends in 3D Printing Technology

Several emerging trends in 3D printing technology are set to impact manufacturing significantly. The growth of industrial 3D printers capable of producing larger and more complex parts is a primary trend. These machines are being integrated into production lines, allowing for faster prototyping and reduced lead times. Additionally, advancements in software and simulation tools are enhancing the design and optimization processes, increasing the overall efficiency of manufacturing operations.Among the noteworthy trends are:

- Digital Inventory: Companies are increasingly adopting digital inventory systems, where products are printed on-demand, eliminating the need for large stockpiles and reducing waste.

- Hybrid Manufacturing: The convergence of traditional manufacturing techniques with 3D printing is creating hybrid systems that leverage the strengths of both methods for improved production quality.

- Mass Customization: As consumer preferences shift towards personalized products, manufacturers are utilizing 3D printing to meet this demand without compromising productivity.

- Automation and AI Integration: The integration of artificial intelligence into 3D printing processes is enabling smarter production systems capable of optimizing designs and minimizing errors.

Advancements in Materials Science, How 3D Printing is Revolutionizing Manufacturing

The future of 3D printing is heavily influenced by advancements in materials science. New materials, including advanced polymers, metals, and biocompatible substances, are being developed to withstand higher temperatures, offer greater strength, and provide increased flexibility. For instance, the introduction of thermoplastics and composite materials is broadening the application spectrum of 3D printing in manufacturing.Innovative materials are leading to:

- Enhanced Performance: Advanced materials are designed to meet specific performance criteria, making them suitable for applications in aerospace, automotive, and healthcare.

- Biodegradable Options: The development of eco-friendly materials is addressing sustainability concerns, allowing for the production of biodegradable products that reduce the environmental impact.

- Metal Alloys: New metal alloys designed for 3D printing can provide superior strength and durability, making them ideal for critical components in industries like aerospace and defense.

The Future of Customization and Personalization

Customization and personalization are expected to be at the forefront of 3D printing’s evolution in manufacturing. Consumers are increasingly seeking unique products tailored to their specific needs, and 3D printing is uniquely suited to fulfill this demand. As technology advances, manufacturers will be able to create highly individualized items at scale, reducing the cost of customization.Key aspects influencing the future of customization include:

- Consumer-Centric Design: Manufacturers are shifting towards a consumer-centric approach, leveraging 3D printing to produce items that reflect individual preferences and lifestyles.

- Shorter Production Cycles: Faster production times afforded by 3D printing allow for rapid prototyping, enabling manufacturers to adjust designs based on consumer feedback quickly.

- Decentralized Manufacturing: Localized production through 3D printing can meet local demands for customized products, reducing shipping costs and lead times.

“The future of 3D printing lies in its ability to create what the consumer truly desires, fostering a new era of personalized manufacturing.”

Challenges and Limitations of 3D Printing

The adoption of 3D printing in manufacturing, while promising, is not without its challenges and limitations. Manufacturers face various hurdles when integrating this technology into their production processes. Understanding these obstacles is key to navigating the landscape of modern manufacturing and maximizing the benefits of 3D printing.

Common Challenges Faced by Manufacturers

Numerous challenges can arise for manufacturers during the transition to 3D printing. These include issues related to the technology itself, integration into existing workflows, and skill set requirements. Key challenges include:

- High Initial Costs: The investment in 3D printing technology and materials can be substantial, particularly for high-end industrial printers.

- Training Requirements: Employees must be trained to operate new machines and software, which can lead to additional costs and a steep learning curve.

- Technology Integration: Incorporating 3D printing into existing production lines poses logistical challenges, including how to seamlessly integrate traditional manufacturing methods with additive manufacturing.

Regulatory Hurdles and Standards

Regulatory challenges are significant for companies looking to produce 3D printed products, especially in industries with stringent safety standards, such as aerospace and medical devices. The lack of established regulations specifically for 3D printed goods raises concerns regarding quality assurance and liability. Important factors include:

- Quality Standards: Ensuring that 3D printed products meet regulatory standards requires the establishment of new quality control protocols specific to additive manufacturing.

- Certification Processes: The processes for certifying 3D printed parts can be lengthy and complex, often delaying time-to-market for new products.

- Intellectual Property Issues: The ease of copying designs in 3D printing raises concerns about intellectual property rights and protections.

Limitations Related to Material Properties

Despite advancements in 3D printing materials, limitations still exist, particularly concerning the mechanical properties and performance of printed parts. Certain materials can hinder the applicability of 3D printing in various scenarios:

- Material Strength: Many 3D printed materials do not match the strength and durability of traditionally manufactured materials, limiting their use in high-stress applications.

- Thermal Properties: Some materials can have poor thermal resistance, making them unsuitable for applications involving high temperatures.

- Surface Finish: The finish of 3D printed parts often requires post-processing, which can add time and cost to production.

Production Speed Limitations

While 3D printing offers rapid prototyping capabilities, the production speed for larger runs can be a significant drawback. The layer-by-layer construction process can lead to longer lead times for mass production. Key points related to this limitation include:

- Build Time: The time taken to print an object can be extensive, particularly for detailed or large designs, affecting overall efficiency.

- Batch Production Challenges: While 3D printing excels in producing unique or low-volume items, scaling up for mass production can be challenging and less efficient compared to traditional methods.

- Downtime and Maintenance: 3D printers require regular maintenance, and machine downtime can disrupt production schedules.

“While 3D printing has transformative potential, understanding its challenges is crucial for successful implementation in manufacturing.”

Environmental Impact of 3D Printing

The environmental impact of 3D printing is a significant factor in its growing adoption across various industries. As traditional manufacturing methods often involve extensive material waste and energy consumption, 3D printing presents a more sustainable alternative. This technology enables the production of parts and products with minimal waste, leading to a reduction in the overall ecological footprint.In 3D printing, material is added layer by layer, utilizing only the necessary amount required for the final product.

This precision not only minimizes waste but also allows for complex designs that were previously difficult or impossible to achieve. Additionally, the sustainability of materials used in 3D printing processes plays a crucial role in its environmental benefits.

Ecological Benefits of Reducing Waste

D printing contributes to waste reduction in several key ways. Unlike traditional subtractive manufacturing, which often involves cutting away excess material, 3D printing utilizes only the material needed for the object being created. This aspect leads to significant resource savings and less environmental impact.

Material Efficiency

3D printing can reduce material waste by up to 90% in some applications, as only the required material is used.

On-Demand Production

The ability to produce parts on-demand means that there is less need for large inventories, which often lead to overproduction and waste.

Sustainability of Materials Used in 3D Printing

The materials employed in 3D printing processes are increasingly being developed to be more sustainable. Many companies are now using biodegradable plastics and recycled materials, further enhancing the environmental credentials of 3D printing.

Biodegradable Filaments

Polylactic acid (PLA), derived from renewable resources like corn starch, offers a sustainable option for 3D printing.

Recycled Materials

Some 3D printers can utilize recycled plastics, turning waste products into new items, thus closing the recycling loop.

Comparison of Environmental Footprints

When comparing the environmental footprints of traditional manufacturing methods to those of 3D printing, the differences are striking. The table below elucidates these contrasts:

| Aspect | Traditional Manufacturing | 3D Printing |

|---|---|---|

| Material Waste | Up to 80% waste due to cutting and machining | Less than 10% waste due to additive processes |

| Energy Consumption | High energy required for machinery and transportation | Lower energy needs with localized production |

| Resource Usage | Utilizes virgin materials predominantly | Incorporates recycled and biodegradable materials |

| Transportation Emissions | High emissions due to global supply chains | Reduced emissions with localized production capabilities |

“3D printing techniques can lead to more sustainable manufacturing practices by reducing waste and utilizing eco-friendly materials.”

The comparison shows that 3D printing offers significant advantages in terms of waste reduction, energy efficiency, and sustainable material use, making it a promising technology for the future of manufacturing.

Integration of 3D Printing with Industry 4.0

The integration of 3D printing within the Industry 4.0 framework marks a significant evolution in manufacturing processes. Industry 4.0 emphasizes the use of automation, data exchange, and smart technology in manufacturing environments, and 3D printing plays a crucial role in this transformation. By synergizing with advanced technologies such as the Internet of Things (IoT) and Artificial Intelligence (AI), 3D printing is not only enhancing production efficiency but also enabling customization and rapid prototyping on an unprecedented scale.The interconnection of 3D printing with Industry 4.0 facilitates a more streamlined, data-driven production environment.

By utilizing real-time data from interconnected devices, manufacturers can optimize processes, reduce waste, and improve product quality. The convergence of these technologies allows for a more agile manufacturing system where changes can be implemented quickly based on immediate feedback from production lines and market demands.

Enhancement of 3D Printing Processes through IoT and AI

The enhancement of 3D printing capabilities through IoT and AI technologies is reshaping how manufacturers approach production. IoT devices collect vast amounts of data regarding machine performance, material usage, and environmental conditions. This data is critical in making informed decisions that lead to optimized production processes. For instance, AI algorithms analyze data from 3D printers to predict potential failures or maintenance needs, thereby reducing downtime and ensuring consistent operation.

Predictive maintenance can be exemplified by a 3D printing facility that utilizes AI to monitor printer health, resulting in a reduction of unexpected breakdowns by up to 30%. Moreover, IoT integration allows for remote monitoring and control of 3D printers. Manufacturers can adjust printing parameters in real-time, enhancing the ability to respond swiftly to changes in production requirements. The data collected can also improve the design iteration process.

For example, feedback loops from the printing process can inform designers on necessary adjustments to improve product performance or reduce material costs.

Implications of Smart Manufacturing on 3D Printing Capabilities

The implications of smart manufacturing on 3D printing capabilities are profound, influencing everything from supply chain management to product design. Smart manufacturing, characterized by interconnected systems and automated processes, enhances the capabilities of 3D printing in several ways:

Customization at Scale Smart manufacturing allows for the production of individualized products without significant cost increases. 3D printing enables the creation of tailored solutions, whether in healthcare with custom prosthetics or in automotive with bespoke parts.

Supply Chain Optimization By integrating 3D printing into smart manufacturing, companies can produce components closer to where they are needed, significantly reducing lead times and logistics costs. This local production model can be vital in industries like aerospace, where parts can be manufactured on-demand.

Sustainability Practices Smart manufacturing methods often prioritize sustainability, and 3D printing aligns with these goals by minimizing material waste and promoting the use of recyclable materials. For instance, companies are increasingly adopting bio-based filaments for 3D printing, which reduce their carbon footprint.

Enhanced Collaboration and Innovation Advanced manufacturing environments foster collaboration between design teams and production units, resulting in innovative product designs that leverage the unique capabilities of 3D printing. Cross-disciplinary teams can iterate more quickly, leading to faster time-to-market for new products.By embracing these advancements, manufacturers are reaping the benefits of enhanced efficiency, improved product quality, and a more sustainable production process. The integration of 3D printing into Industry 4.0 is not merely a trend but a fundamental shift that is defining the future of manufacturing.